If you’re trying to choose between an edge sealer and a chamber sealer, it depends on your needs. Edge sealers are simple, compact, and ideal for small-scale tasks like sealing small bags quickly and affordably. Chamber sealers, on the other hand, handle larger, irregularly shaped bags, provide higher quality vacuum seals, and are better for long-term food preservation or bulk packaging. To understand which type suits your project best, explore the key differences and benefits further.

Key Takeaways

- Edge sealers create airtight seals along the bag edges, ideal for small-scale, quick, and simple packaging tasks.

- Chamber sealers vacuum entire bags inside a sealed chamber, suitable for larger, irregular, or liquid-filled items.

- Edge sealers are compact, affordable, and require minimal maintenance, while chamber sealers are larger, more costly, and handle higher volume.

- Chamber sealers provide stronger, longer-lasting seals with better air removal, extending food shelf life more effectively.

- Choose edge sealers for small, lightweight items; opt for chamber sealers for bulk, complex, or liquid packaging needs.

What Are Edge Sealers and How Do They Work?

Edge sealers are specialized vacuum sealing machines designed to create airtight seals along the edges of bags or pouches. They use advanced sealing technology to guarantee a secure, consistent closure, which is vital for preserving food and other items. These sealers are typically compatible with a variety of materials, including polyethylene, nylon, and specialty laminates, making them versatile for different packaging needs. By applying heat and pressure, edge sealers fuse the bag’s opening, preventing air and moisture from entering. Their straightforward design allows for quick operation, making them ideal for small-scale or high-turnover environments. Understanding material compatibility ensures you select the right bags, avoiding leaks or damage. Additionally, proper sealing techniques can mitigate the risks associated with manipulative tactics like gaslighting or deception used in dark psychology. Proper training and knowledge of sealing procedures can also improve overall packaging quality and reduce waste. Choosing the appropriate sealing method can also impact the overall efficiency of packaging, especially in commercial settings. Overall, edge sealers provide an efficient, reliable method for creating durable, airtight seals.

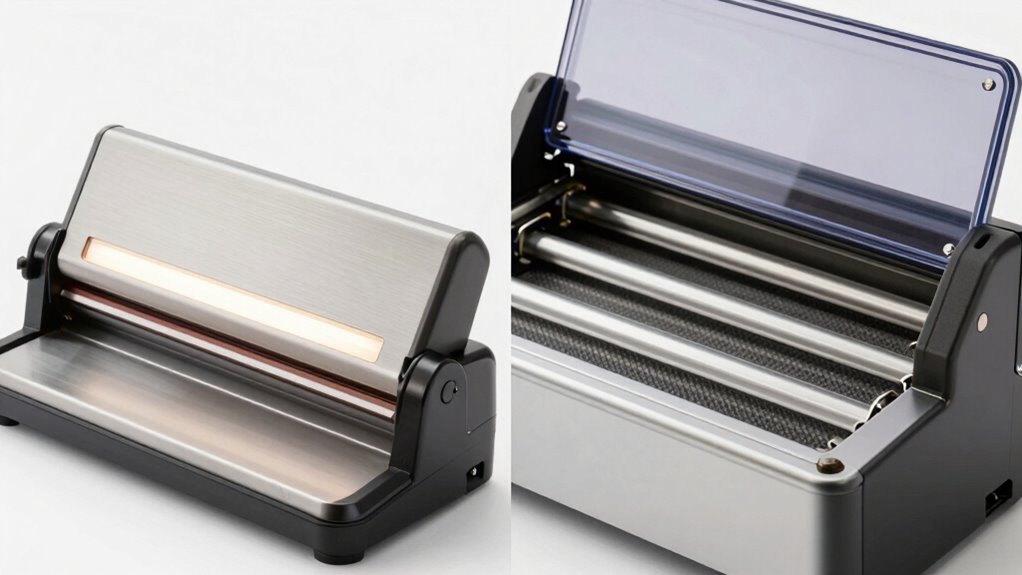

How Do Edge Sealers and Chamber Sealers Differ in Design and Function?

While both edge sealers and chamber sealers serve to vacuum-pack items, they differ substantially in design and operation. Edge sealers use a sealing bar along the bag’s edge, relying on a simple sealing mechanism to create an airtight seal. They are typically user-friendly, with straightforward interfaces that focus on manual control. Chamber sealers, however, have a sealed chamber where you place the entire bag, and the vacuum is applied inside the chamber. Their sealing mechanism is more complex, often offering advanced features like adjustable vacuum and sealing settings. The user interface on chamber sealers is usually more sophisticated, providing digital controls or touchscreens for precise operation. These differences impact how you operate each type and determine their suitability for various packaging needs. Additionally, vacuum technology influences the overall performance and image quality of projectors, with different methods affecting color fidelity and contrast ratios.

When Should You Use an Edge Sealer?

Use an edge sealer when you need to package small items quickly and easily. It’s ideal for limited bag sizes and straightforward sealing tasks. If your needs are simple and efficient, an edge sealer is a practical choice. Additionally, play-based learning can help children develop resilience and a growth mindset, which are important for mental health. For specific applications, understanding free floating techniques can optimize sealing effectiveness and reduce waste. Mastering sealing techniques can further improve packaging efficiency and durability. Being familiar with sealing parameters ensures consistent results across various projects. Knowing how to maintain proper ventilation during sealing can also prevent overheating and ensure safety.

Suitable For Small Items

If you’re sealing small items like herbs, jewelry, or delicate snacks, an edge sealer offers a quick and efficient solution. It’s ideal for small item packaging because it’s designed to handle tiny, lightweight objects without damaging them. When delicate item sealing is needed, an edge sealer provides a controlled, airtight seal that prevents crushing or tearing fragile items. This type of sealer is perfect when speed and simplicity are priorities, especially for items that don’t require large vacuum chambers. Its compact design makes it easy to use for small-scale tasks, such as preserving herbs or sealing jewelry for storage or transport. Use an edge sealer whenever you need a reliable, straightforward method to secure small, delicate objects quickly and efficiently. Additionally, choosing the right sealer can help you achieve a professional look similar to celebrity style DIY projects, ensuring your items are preserved with care and precision.

Quick and Easy Process

Wondering when an edge sealer offers the quickest and simplest sealing process? If you frequently work with standard vacuum bag materials like plastic or nylon, an edge sealer is a great choice. Its sealing speed is fast because it uses a straightforward heat seal along the bag’s edge, making it ideal for small batches or quick packaging tasks. You don’t need to worry about complex chamber setups or large bags; just place the bag in the sealer, press the button, and you’re done. This simplicity means less time spent on preparation and faster results, perfect for everyday use or when you need sealed bags in a hurry. Overall, an edge sealer provides a quick, efficient solution for sealing standard vacuum bags with minimal effort.

Limited Bag Sizes

Since edge sealers are designed for smaller, straightforward bags, they’re ideal when working with limited bag sizes. Their bag size limitations mean they work best with standard-sized bags, typically up to a certain width and length, due to sealing capacity constraints. If you often seal small portions or pre-cut bags, an edge sealer offers a quick and efficient solution without the need for larger equipment. However, if you regularly handle larger or irregularly shaped bags, an edge sealer’s sealing capacity constraints might limit your options. In such cases, a chamber sealer could be more suitable. Use an edge sealer when your packaging needs are simple, your bags are consistently small, and you want a cost-effective, easy-to-use device that handles limited bag sizes efficiently. Additionally, understanding the market reputation of different sealers can help you choose a reliable and trusted product.

What Are the Benefits of Chamber Sealers for Food Preservation and Business?

Chamber sealers can considerably extend the shelf life of your food, reducing waste and saving money. They also boost your business efficiency by allowing faster and more consistent packaging. With these benefits, you can preserve quality and increase productivity simultaneously. Additionally, using a chamber sealer can improve the food preservation process by providing a more airtight seal that maintains freshness longer. Incorporating measurement tools like pressure gauges ensures optimal sealing conditions and consistent results.

Enhanced Food Longevity

Chamber sealers considerably extend the shelf life of preserved foods by removing all air and creating a durable, airtight seal. This process prevents oxidation, bacteria growth, and freezer burn, keeping food fresh longer. You can enhance food preservation by using marination techniques, as chamber sealers allow liquids and marinades to be infused directly into the packaging. Additionally, vacuum sealer accessories like specialized bags or marination trays optimize the process. The extended longevity benefits are especially valuable for bulk storage, meal prepping, or commercial use, where maintaining freshness is vital.

| Feature | Benefit |

|---|---|

| Airtight sealing | Prevents spoilage and freezer burn |

| Full air removal | Extends food shelf life markedly |

| Marination compatibility | Enhances flavor infusion without leakage |

| Durable packaging | Protects against punctures and tears |

| Versatile accessories | Enables customization for various preservation needs |

Increased Business Efficiency

Utilizing chamber sealers can considerably boost your business’s efficiency by streamlining food preservation processes. With advanced sealing technology, chamber sealers create a stronger, more reliable vacuum, reducing waste and spoilage. They work well with various vacuum bag types, allowing you to choose the best options for different products. This versatility speeds up packaging, ensuring quicker turnaround times. Chamber sealers also minimize operator error by providing consistent results, which means less rework and higher productivity. Their ability to handle larger quantities at once makes them ideal for high-volume operations. Overall, adopting chamber sealing technology helps you save time, cut costs, and improve your product quality—giving your business a competitive edge in food preservation and packaging.

How Do Cost, Size, and Maintenance Compare for Both Sealers?

When comparing different types of vacuum sealers, cost, size, and maintenance are key factors to contemplate. In terms of cost comparison, edge sealers are generally more affordable upfront, making them ideal for home use or small businesses. Chamber sealers tend to be pricier but offer better efficiency for bulk sealing. Size-wise, edge sealers are compact and lightweight, saving space, while chamber sealers are larger and require more room. Maintenance requirements also differ: edge sealers usually need minimal upkeep, mainly replacing sealing strips, whereas chamber sealers may require more attention to their vacuum pumps and seals. Additionally, understanding sealing efficiency can help determine which type is better suited to your needs. Overall, your choice depends on your budget, available space, and how much time you’re willing to invest in maintenance.

How to Choose the Right Vacuum Sealer for Your Needs?

Figuring out which vacuum sealer is right for you depends on understanding your specific needs and how you plan to use it. Consider the following when choosing your device: 1. The volume of vacuum packaging you’ll do regularly, whether for small portions or large quantities. 2. The type of sealing technology that suits your items—edge sealers are great for food prep, while chamber sealers excel with liquids and fragile goods. 3. Your available space and budget, shaping whether a compact, affordable model or a professional-grade unit makes sense. Additionally, understanding the future economic trends can help you make a more informed investment in quality equipment. Being aware of market demand and potential technological advances can guide you toward a more durable and versatile choice. Considering technological innovations can also provide insight into emerging features that might benefit your packaging needs. Recognizing industry standards can ensure that your chosen equipment meets safety and efficiency requirements. Moreover, staying informed about regulatory changes can help you maintain compliance and avoid potential issues down the line.

FAQs: Deciding Between Edge and Chamber Sealers

Choosing between edge and chamber sealers can seem tricky, but understanding their key differences helps simplify the decision. If you need better air quality control or plan to use the sealer for industrial applications, a chamber sealer might be best due to its higher vacuum strength and ability to handle larger quantities. Edge sealers are more suitable for home use and small-scale tasks.

| Feature | Suitable for |

|---|---|

| Air quality control | Chamber sealers |

| Small-scale use | Edge sealers |

| Industrial applications | Chamber sealers |

Deciding depends on your volume and application needs. Chamber sealers provide a more consistent vacuum for industrial tasks, while edge sealers are easier and more affordable for occasional use.

Frequently Asked Questions

Can Both Sealer Types Handle Liquids Effectively?

Both sealer types can handle liquids, but their effectiveness varies. Chamber sealers excel at liquid handling because they evacuate air completely before sealing, ensuring better seal integrity even with liquids. Edge sealers struggle with liquids, as excess moisture can compromise the seal. If you frequently package liquids, a chamber sealer offers more reliable performance, maintaining seal integrity and preventing leaks.

Which Sealer Is Better for Commercial Versus Home Use?

You’ll find that chamber sealers excel for commercial use, offering industrial efficiency and the ability to handle large volumes with ease. They’re perfect for professional environments where durability and consistency matter. For home use, edge sealers shine due to their user convenience and simplicity. While they may lack high-volume capacity, they’re more affordable and easier to operate. Choosing depends on your needs—if you want power and efficiency, chamber is better; for convenience, go with edge.

Are There Specific Foods Better Suited for Each Sealer Type?

You’ll find that certain foods are better suited for each sealer type to optimize food preservation and packaging efficiency. For delicate items like berries or sliced produce, an edge sealer works well because it’s gentle and quick. For bulk meats, cheeses, or liquids, a chamber sealer offers superior sealing, preventing leaks and maintaining freshness. Selecting the right sealer guarantees your food stays fresh longer and maximizes your preservation efforts.

How Long Does Each Sealer Typically Last?

Did you know that a chamber sealer typically lasts 5 to 10 years with proper maintenance? Both types depend on sealing strength and regular upkeep. Edge sealers usually need less maintenance and can last longer, around 3 to 5 years. Chamber sealers, while more durable, require more frequent cleaning and checks. Proper maintenance extends their lifespan, ensuring you get the most out of your investment.

What Are the Safety Features Common to Both Sealers?

Both types of sealers typically include safety features like safety alarms that alert you to issues such as overheating or improper sealing. They also have pressure release mechanisms to prevent excess pressure buildup, ensuring safe operation. These features help protect you from potential hazards, making vacuum sealing safer and more reliable. Always follow the manufacturer’s instructions to maximize safety and performance.

Conclusion

Choosing between an edge sealer and a chamber sealer can feel like deciding between a bicycle and a spaceship. But remember, your choice can totally transform your food storage or business—saving you hours, money, and headaches! Whether you need quick, simple sealing or heavy-duty, professional-grade preservation, the right sealer will elevate your game. So go ahead, pick wisely—because this decision could be the game-changer that makes your food last forever and your profits soar!